搅拌摩擦焊网讯 近日,机械工程领域国际顶级期刊International Journal of Machine Tools and Manufacture(简写IJMTM)发表了山东大学材料科学与工程学院武传松教授课题组的研究成果“Constitutive equation including acoustic stress work and plastic strain for modeling ultrasonic vibration assisted friction stir welding process”。材料学院博士研究生赵文祯为该文第一作者,武传松教授为通讯作者,山东大学为唯一完成单位。

随着国家经济建设和社会可持续发展对节能、减排和环保的要求不断提高,轻量化设计与制造在汽车、高速列车和航空航天等行业得到越来越多的应用。而铝合金、镁合金等轻质材料的高效和优质焊接成形,是轻量化结构制造亟待解决的关键问题。武传松教授课题组发明了超声辅助搅拌摩擦焊接新工艺UaFSW,在铝合金、镁合金等轻质材料的焊接方面取得了很好的工艺效果。但是,急需对其工艺机理开展深入研究。为此,武传松教授课题组提出了新颖的材料本构方程修正方法,分析了焊具高速旋转与振动带来的协同效应、超声振动引起的声致软化效应等,揭示了施加于焊具之上的超声振动对焊具周围热-力过程的影响规律,开展了充分的实验验证。研究结果为提高铝合金、镁合金等轻质材料构件的焊接制造水平奠定了坚实基础。

IJMTM被公认为是机械工程领域的TOP期刊,在全球129种机械工程SCI收录期刊中排名第三(TOP 3),五年影响因子6.565。 本项研究工作得到了国家自然科学基金和山东省重点研发计划项目的资助。 论文链接:https://doi.org/10.1016/j.ijmachtools.2019.103434

(原标题:武传松教授团队在机械工程领域国际顶级期刊IJMTM发表铝合金UaFSW焊接新工艺机理的最新成果 作者:宿浩)

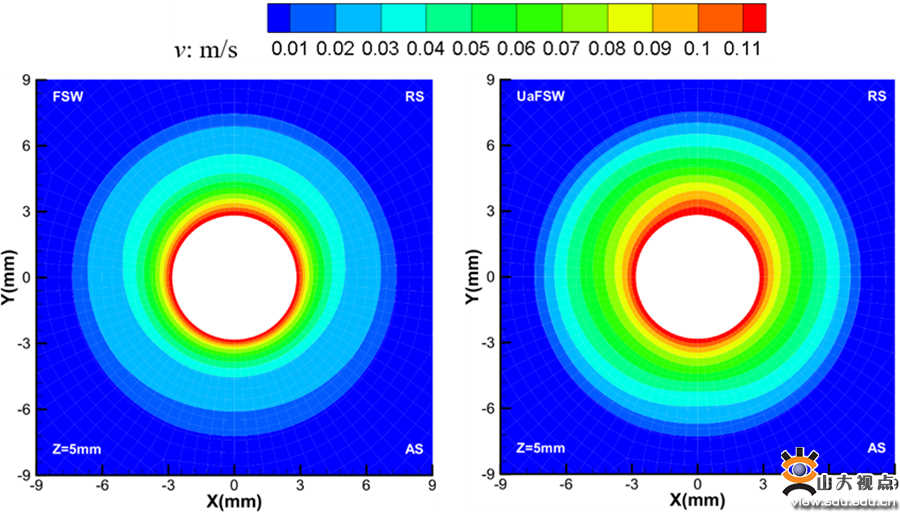

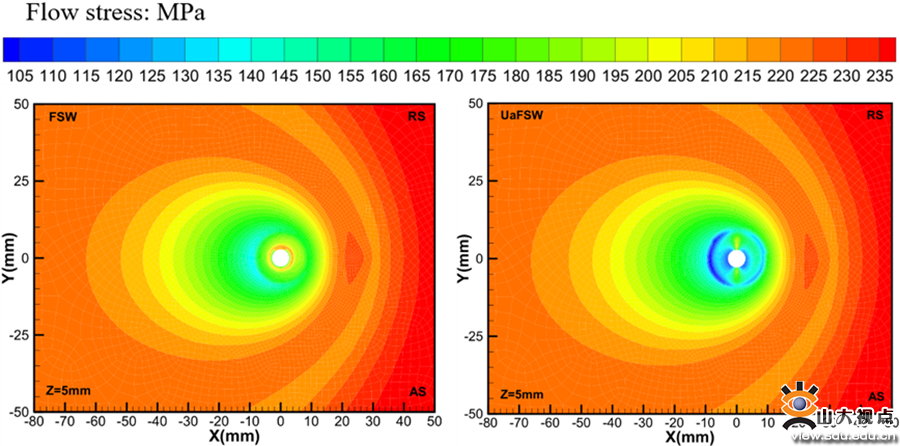

Abstract:To reveal the underlying mechanism of the synchronous interaction between the ultrasonic vibration exerted onto the welding tool along welding direction and the thermo-mechanical behavior induced by the tool’ rotation and traverse, two available constitutive equations are combined together by including various influencing factors such as strain, strain rate and temperature. A modified constitutive equation considering the acoustic stress work and a method determining the flow stress are proposed and experimentally calibrated. Both are employed in modeling ultrasonic vibration assisted friction stir welding process (UaFSW) to characterize the effect of acoustic softening on the plastic deformation of aluminum alloy in UaFSW process. Numerical simulation of flow stress, strain/strain rate and plastic material flow as well as ultrasonic field is carried out to explain the reason why ultrasonic vibration exerted onto the tool in this way could reduce the flow stress and promote the plastic material flow in UaFSW. The model is validated by comparing the predicted and experimentally measured profile of thermo-mechanically affected zone.

Keywords :Friction stir weldingConstitutive equationUltrasonic vibrationAcoustic stress workAcoustic softening effectNumerical simulation